Foundry Industrial Furnaces

Foundries cast parts out of steel, aluminum, and other metals using different casting processes depending on the part production rate, the intricacy of the finished part, and the metal being cast. During the casting process, liquid metal is poured into a mold and then allowed to cool and solidify. A non-ferrous melting furnace is used to melt the metal prior to being poured in the mold. After the cast is cooled it may require further heat treating in an industrial furnace to strengthen the metal. In addition to non-ferrous melting and holding equipment, Lindberg/MPH also supplies industrial furnaces to the foundry industry for heat treating applications.

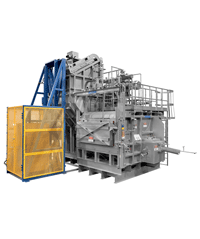

Industrial foundry furnaces designed and built by Lindberg/MPH allows you to increase production efficiency while producing uniform results.