Industrial Sintering Furnace

Sintering Process

The sintering process is used to compact a powder into a solid with the application of heat or pressure. The substance is heated in a sintering furnace to a temperature lower than the melting point which causes the powder particles to bond together into a compact mass. The part is strengthened by the bonding process that happens in an industrial sintering furnace.

Electronics Mesh Belt Conveyor Furnace

High yields of uniform quality products. These highly efficient and economical furnaces are designed for atmosphere and nonatmosphere applications at temperatures up to 2100°F (1150°C).

Available

Key Specifications

- Temperature Range: up to 1100°C

- Maximum energy efficiency and long service life

- Control of belt speed, temperature, and atmosphere

- Optional combustible atmosphere system

Sintering Mesh Belt Conveyor Furnace

Designed to accommodate a variety of heat-treating processes. Excess temperature safety system guards product against temperature conditions. Easy Installation and a low cost.

Key Specifications

- Temperature Range: to 2100°F

- Excess temperature safety system guards product against temperature conditions

- Available in a variety of sizes and belt widths

- Optional binder eductor system

Roller Hearth Furnace

These roller hearth furnaces are designed for annealing, brazing, sintering, stress relieving, normalizing, tempering, hardening and other applications that require process temperatures up to 2050°F (1121°C). The roller hearth furnaces can be furnished in various widths and load-handling capabilities. Combination preheat and high heat zones are available for brazing applications.

Key Specifications

- Complete, systems ready for operation

- Easy and safe operation and process repeatability

- Convenient access to controls and maintenance items

- Optional programmable controller(s)

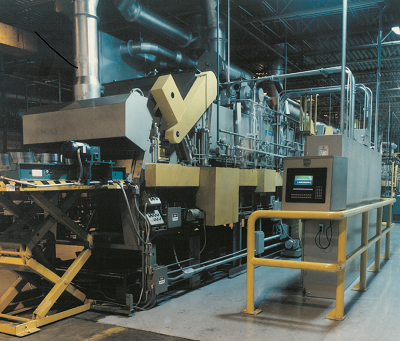

Lindberg Walking Beam Furnace

The Lindberg Walking Beam Furnace is a popular choice for sintering metallic and ceramic materials under controlled atmosphere. These energy efficient and cost effective Lindberg walking beam furnaces are capable of processing heavy loads at high production rates. Temperature range: up to 3272°F (1800°C) in reducing atmospheres.

Key Features

- Protected yet accessible hydraulic system

- Reliable and adaptable load transfer

- Flexible sequence control system featuring microprocessor based programmable control

- Proven refractory system

- Solid, round rod molybenum heating elements

- Multi-atmosphere capabilities & Rugged construction