Industrial Normalizing Furnace

Normalizing Process

During the normalizing process metal is heated to a temperature and then held at that temperature for a specified amount of time. After the metal is finished with the heating process, it is air cooled at room temperature. The resulting microstructure has increased strength and hardness but lower ductility because it is a mixture of ferrite and cementite. The normalizing process is commonly performed in an industrial box furnace, pit or top load furnace, or integral quench furnace.

Rod Overbend Box Furnace

The Rod Overbend (RO) electric box furnace gives you flexible, efficient performance in a variety of heat treating applications.

Key Specifications

- Temperature Range: to 2000°F

- Atmosphere Capable

- Fast heating rate

- Exothermic, dissociated ammonia, or nitrogen atmosphere systems

Silicon Carbide Element Box Furnace

The Lindberg/MPH SC (silicon carbide element) box furnace is designed to deliver precision high temperature uniformity required in the treating of high alloy and high speed tool steels.

Key Specifications

- Temperature Range: to 2500°F

- Standard endothermic atmosphere system

- Heating element circuit power transformer with tap switches

- Optional carbon control with oxygen probe

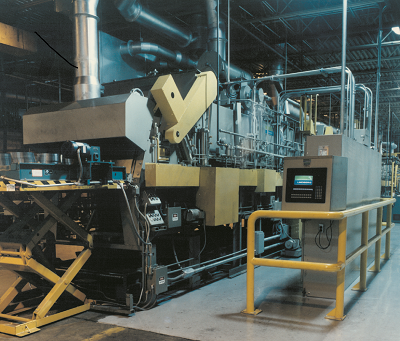

Car Bottom Box Furnace

Lindberg/MPH manufactures fuel fired, electric powered and dual energy car bottom furnaces for batch processing large parts at temperature up to 2800°F.

Key Specifications

- Temperature Range: to 2800°F

- Gas or electric heat available

- Innovative and lightweight modular design for easy installation

- Modular construction

HOMOCARB® Pit Furnace

These electric powered pit furnaces are designed to work with protective carbonaceous atmosphere.

Key Specifications

- Temperature Range: up to 1750°F

- Inert or Combustible Atmosphere Capable

- Microprocessor-based controls

- Optional automatic atmosphere control system

Electronics Mesh Belt Conveyor Furnace

High yields of uniform quality products. These highly efficient and economical furnaces are designed for atmosphere and nonatmosphere applications at temperatures up to 2100°F (1150°C).

Available

Key Specifications

- Temperature Range: up to 1100°C

- Maximum energy efficiency and long service life

- Control of belt speed, temperature, and atmosphere

- Optional combustible atmosphere system

Roller Hearth Furnace

These roller hearth furnaces are designed for annealing, brazing, sintering, stress relieving, normalizing, tempering, hardening and other applications that require process temperatures up to 2050°F (1121°C). The roller hearth furnaces can be furnished in various widths and load-handling capabilities. Combination preheat and high heat zones are available for brazing applications.

Key Specifications

- Complete, systems ready for operation

- Easy and safe operation and process repeatability

- Convenient access to controls and maintenance items

- Optional programmable controller(s)

Rotary Hearth Furnace

The rotary hearth furnace is used primarily for gear hardening type applications that require process quenching.

Key Specifications

- Temperature Range: up to 2500°F

- Variable speed

- Excess temperature instrument

- Optional carbon control with oxygen probe

Rod Overbend Pit Furnace

The Rod Overbend (RO) pit furnace gives you flexible, efficient performance in a variety of heat treat applications including annealing, normalizing and hardening at temperatures up to 1850°F (2000°F optional).

Key Specifications

- Temperature Range: to 1850°F

- Inert or Combustible Atmosphere Capable

- Standard endothermic atmosphere system

- Easy-loading vertical chamber