Industrial Carburizing Furnace

Carburizing Process

The carburizing process, also known as case hardening, is the application of heat to diffuse carbon into the surface of the steel creating a thinner, harder layer of metal, known as the surface case, which strengthens the piece and prevents corrosion. While carburizing creates a tough outer case it still maintains the strength of the core at a lower hardness level. Carburization is commonly used after machining on low carbon steel parts and other alloys. The process of carburizing is performed in a heat treat furnace such as an integral quench furnace or pit furnace.

Corrtherm Element Electric Box Furnace

The rugged Lindberg/MPH Corrtherm electric box furnace offers a unique combination of high performance and low maintenance.

Key Specifications

- Temperature Range: to 1850°F

- Combustible

atmosphere available - Thick cross-section, low voltage Corrtherm heating elements

- Durable design for years of worry free use

Corrtherm Element Pit Furnace

The Corrtherm pit furnace offers a unique combination of big performance and low maintenance at temperatures up to 1850°F.

Key Specifications

- Temperature Range: to 1850°F

- Inert or Combustible Atmosphere Capable

- Ideal for cell/JIT installations

- Low power consumption and fast cycle times.

HOMOCARB® Pit Furnace

These electric powered pit furnaces are designed to work with protective carbonaceous atmosphere.

Key Specifications

- Temperature Range: up to 1750°F

- Inert or Combustible Atmosphere Capable

- Microprocessor-based controls

- Optional automatic atmosphere control system

Rod Overbend Pit Furnace

The Rod Overbend (RO) pit furnace gives you flexible, efficient performance in a variety of heat treat applications including annealing, normalizing and hardening at temperatures up to 1850°F (2000°F optional).

Key Specifications

- Temperature Range: to 1850°F

- Inert or Combustible Atmosphere Capable

- Standard endothermic atmosphere system

- Easy-loading vertical chamber

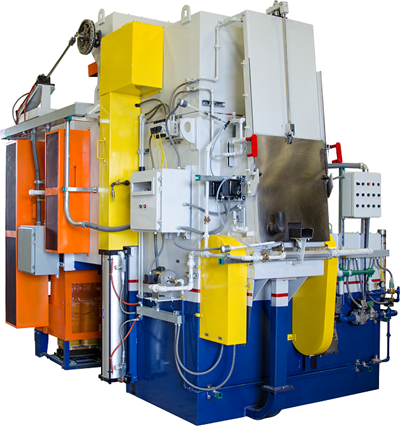

Lindberg/MPH Integral Quench Furnace System

The Lindberg Pacemaker® is a highly productive and efficient integral-quench furnace available in either gas-fired or electric models.

Key Specifications

- Temperature Range: 1925°F maximum

- Size and in-out configurations to suit your exact needs

- Obstruction-free work chambers

- Optional upper atmosphere cooling

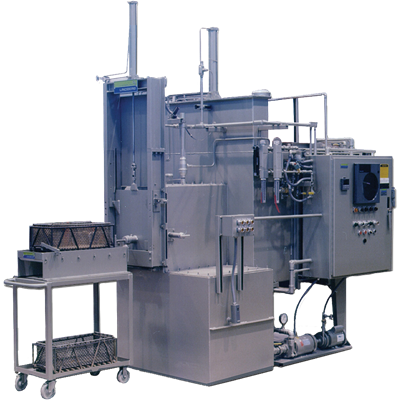

Lindberg/MPH Manual SL Integral Quench Furnace System

The Pacemaker SL is an electrically powered, integral quench furnace capable of temperatures up to 1925°F.

Key Specifications

- Temperature Range: 1925°F maximum

- High temperature range allows for treatment of many tool steel grades

- Lightweight ceramic block insulation

- Optional systems for endothermic or nitrogen-methanol atmospheres