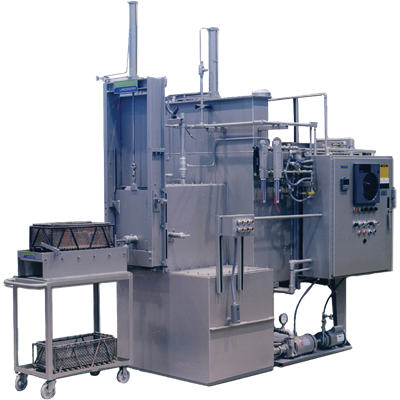

The Manual SL Integral Quench Furnace System is electrically powered and capable of temperatures up to 1925°F. The SL Integral Quench Furnace System offers a compact footprint and competitive price which gives you the benefit of maximizing your production with quick ROI.

Benefits

- Compact system saves space in crowded work areas

- Economical cost

- High temperature range allows for treatment of many tool steel grades

- Easy and smooth operation

- Energy-efficient system design

Features

- 4' x 7' footprint

- Lightweight ceramic block insulation

- Electrically powered

- Electric or gas heat

- Standard inert atmosphere system using nitrogen or argon

- Pushbutton operating of doors and elevator

- Roller rail hearth

- Pre-piped and wired for 230V/2Ph/60Hz service, no pit required

Performance

- Maximum temperature: 1925°F (1800°F with combustible atmosphere)

- 12" x 24" x 12" workspace handles loads to 120 lbs. net.

Options

- Systems for endothermic or nitrogen-methanol atmospheres

- Programmable temperature and atmosphere controls

- Carbon control with oxygen probe

- Ammonia system for carbonnitriding

- Quench Guard oil monitoring system

- Digital recorder

- Loading cart

- Companion draw furnace and washer

- Step-down transformer 480V-230V