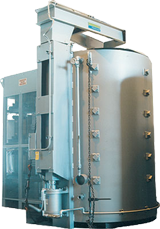

The Corrtherm element pit type furnace offers a unique combination of high performance and low maintenance at temperatures up to 1850°F. Thick cross section, low voltage Corrtherm heating elements completely eliminate the need for a retort, even in high carbon atmospheres. The absence of a retort in this top loading furnace allows for increased part size and improved temperature uniformity. It also eliminates cracking and other maintenance problems inherent with retorts.

Benefits

- Ideal for cell/JIT installations

- Low power consumption and fast cycle times

- Energy efficiency and reliability

- Minimal maintenance

- Excellent uniformity

Features

- Inert or Combustible Atmosphere Capable

- Compact size

- Long-life Corrtherm® elements

- Moldatherm® insulation

- Cover-mounted circulating fan

- Standard endothermic atmosphere system

Options

- Carbon control with oxygen probe

- Gas flowmeters for dissociated ammonia or endothermic atmospheres

- Nitrogen-methanol atmosphere system

- Automatic nitrogen purge

- Control and recording instruments

Applications

- Annealing

- Carburizing

- Carbonitriding

- Hardening

- Normalizing

- Preheating