Industrial Hardening Furnace

Hardening Process

The hardening heat treat process uses heat to increase the hardness of the surface of the material which in turn decreases its vulnerability. Hardening results in a tough outer case and a strong core. The hardening process is done in an industrial heat treat furnace.

Rod Overbend Box Furnace

The Rod Overbend (RO) electric box furnace gives you flexible, efficient performance in a variety of heat treating applications.

Key Specifications

- Temperature Range: to 2000°F

- Atmosphere Capable

- Fast heating rate

- Exothermic, dissociated ammonia, or nitrogen atmosphere systems

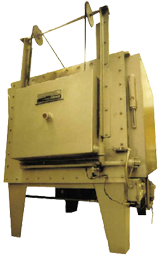

2000° F Utility Box Furnace

The air atmosphere box furnace provides flexible, efficient performance for a variety of heat treating applications. It features a fast heating rate and heavy load capability for increased productivity.

Key Specifications

- Temperature Range: up to 2000°F

- Four (4) standard sizes

- Pneumatically operated door

Silicon Carbide Element Box Furnace

The Lindberg/MPH SC (silicon carbide element) box furnace is designed to deliver precision high temperature uniformity required in the treating of high alloy and high speed tool steels.

Key Specifications

- Temperature Range: to 2500°F

- Standard endothermic atmosphere system

- Heating element circuit power transformer with tap switches

- Optional carbon control with oxygen probe

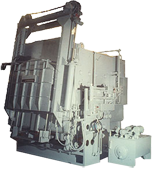

Corrtherm Element Electric Box Furnace

The rugged Lindberg/MPH Corrtherm electric box furnace offers a unique combination of high performance and low maintenance.

Key Specifications

- Temperature Range: to 1850°F

- Combustible

atmosphere available - Thick cross-section, low voltage Corrtherm heating elements

- Durable design for years of worry free use

Gas-Fired Radiant Tube Box Furnace

For efficient, economical performance, the Lindberg Gas-Fired Radiant Tube Box Furnace offers a unique combination of high performance and low maintenance. It is designed for both light or heavy work loads.

Key Specifications

- Temperature Range: to 2000°F

- Efficient and economical performance

- Designed for light or heavy work loads, catering to fluctuating needs

- Automatic gas-air flame curtain burner

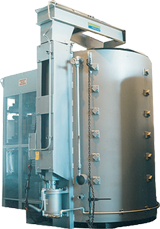

Corrtherm Element Pit Furnace

The Corrtherm pit furnace offers a unique combination of hig performance and low maintenance at temperatures up to 1850°F.

Key Specifications

- Temperature Range: to 1850°F

- Inert or Combustible Atmosphere Capable

- Ideal for cell/JIT installations

- Low power consumption and fast cycle times.

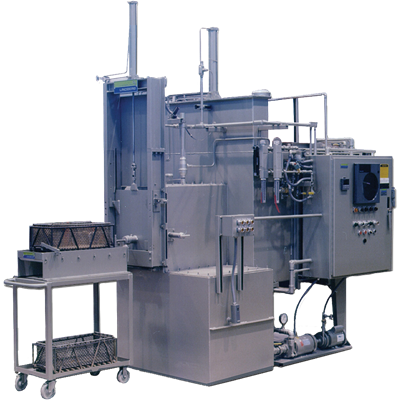

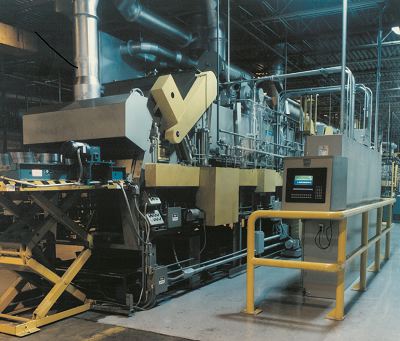

Lindberg/MPH Manual SL Integral Quench Furnace System

The Pacemaker SL is an electrically powered, integral quench furnace capable of temperatures up to 1925°F.

Key Specifications

- Temperature Range: 1925°F maximum

- High temperature range allows for treatment of many tool steel grades

- Lightweight ceramic block insulation

- Optional systems for endothermic or nitrogen-methanol atmospheres

Roller Hearth Furnace

These roller hearth furnaces are designed for annealing, brazing, sintering, stress relieving, normalizing, tempering, hardening and other applications that require process temperatures up to 2050°F (1121°C). The roller hearth furnaces can be furnished in various widths and load-handling capabilities. Combination preheat and high heat zones are available for brazing applications.

Key Specifications

- Complete, systems ready for operation

- Easy and safe operation and process repeatability

- Convenient access to controls and maintenance items

- Optional programmable controller(s

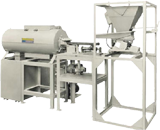

Shaker Hearth Furnace

Electrically heated continuous shaker hearth furnaces with quench tanks for processes such as hardening, carburizing on small screw springs and balls.

Key Specifications

- Temperature Range: 1900°F

- Low Power Cost

- Alloy welded muffle

- SCR power control

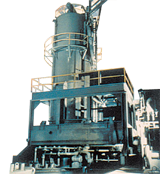

Rotary Hearth Furnace

The rotary hearth furnace is used primarily for gear hardening type applications that require process quenching.

Key Specifications

- Temperature Range: up to 2500°F

- Variable speed

- Excess temperature instrument

- Optional carbon control with oxygen probe