Lindberg/MPH announced the shipment of a three-zone tube furnace to an American University. The tube furnace is ideal for annealing, ashing, carbon and ceramic firing, drying, hardening, sintering, solution treating, stress relieving, and normalizing applications. It offers a small footprint which makes it ideal for research facilities with limited space.

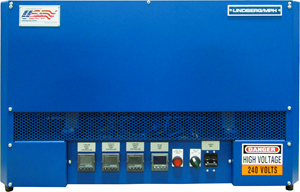

This tube furnace is designed for use where exceptional radial and linear temperature uniformity, process repeatability, rapid heat-up and response are critical. The maximum temperature rating for this tube furnace is 1100°C. The work chamber can accept process tubes 1” to 3” diameter x 24” heated length with three-zones. The furnace utilizes three (3) independent, programmable controllers, one for each zone.

Built for maximum versatility, this three-zone tube furnace is bored to accept process tubes up to 3” when used with an optional tube adapter kit. It incorporates venting and insulating air spaces which provide a cool furnace exterior during furnace operation. The tube furnace also comes with an Exclusive 1-Year Warranty which covers all materials for all components (less wear items).

“This Lindberg/MPH solid tube furnace features an energy efficient design at an economical price. The Moldatherm®, ceramic fiber insulation provides exceptional temperature uniformity, energy efficiency, and fast heat-up and recovery rates.” -Shaina Scott, Applications Engineer

Unique features of this Lindberg/MPH tube furnace include:

- Self-tuning 16 segment digital programmable controls

- Patented Moldatherm® LGO™ heating element modules

- Long-life, energy efficient elements

- Unique cabinet design

- Heat reflecting element support assembly

- Innovative use of venting and insulating air spaces

- Accepts interchangeable Moldatherm® tube adapters

- Long-life Platinel® II thermocouple(s) with 10' compensated lead wire and polarized plug

#227215