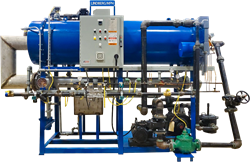

Lindberg/MPH announced the shipment of a gas-fired exothermic atmosphere generator to the manufacturing industry.

The HYEX exothermic atmosphere generator features an energy efficient design that provides reliable and economic operation. The maximum exothermic gas output for this generator is 8,000 feet cubed (ft³) per hour.

The combustion chamber is a reinforced, water jacketed, steel shell that is insulated with a high temperature refractory lining and uses a variable ratio tunnel main burner. The chamber includes UV flame detection and peep sight so the operator can observe the operation of the main burner. In the event of a backfire, a fire-check at the burner inlet will automatically block the mixture line and an electrically latched manual reset valve in the gas inlet line will shut down the generator in the event of low gas pressure, high gas pressure, or electric failure.

The mixing control system for exothermic gas generation utilizes a Waukee precision carburetor for proper blending of incoming gas and air. A gas regulator reduces and stabilizes gas pressure to the carburetor even when the main plant supply is varied. A cooling system rapidly cools the generated gas to condense out moisture. The dew point of the produced HYEX atmosphere gas is approximately 10°F above the temperature of the inlet cooling water.

“The HYEX generator design allows for varying air/gas ratios to create atmospheres specific to your process. This exothermic gas generator provides an impressive 8,000 feet cubed (ft³) per hour maximum gas output.”

- Kelley Shreve, General Manager

Unique features of this atmosphere generator include:

Energy efficient and reliable design for economical operation

UV flame detection and peep sight

Varying air/gas ratios create atmospheres to meet application requirements

Variable ratio tunnel main burner

Completely assembled unit on one base

#236733