Industry’s single source for heat treat and melting solutions

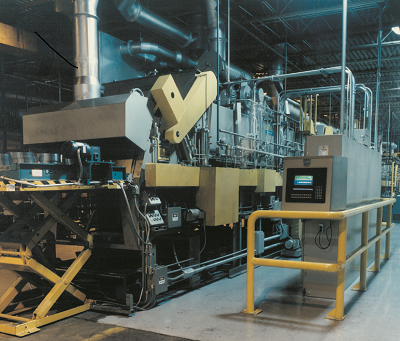

These roller hearth furnaces are designed for annealing, brazing, sintering, stress relieving, normalizing, tempering, hardening and other applications that require process temperatures up to 2050°F (1121°C). The roller hearth furnaces can be furnished in various widths and load-handling capabilities. Combination preheat and high heat zones are available for brazing applications.