Heat Treat Furnaces

About Heat Treating & Heat Treat Furnaces

Heat treating (or heat treatment) broadly refers to a group of thermal processes in industrial and metalworking applications used to intentionally alter the physical, and sometimes chemical, properties of a material (usually a metal). These physical and chemical property alterations typically come in the form of hardening or softening of a material via heating in a high temperature furnace or chilling at extreme temperatures. Heat treating occurs at temperatures above 1,000° F, and often in excess of 1,700° F.

Desired workpiece physical and chemical properties are achieved through heat treatment techniques such as annealing, case hardening, precipitation, strengthening, tempering, normalizing, and quenching. Lindberg/MPH designs and manufactures thermal processing and high temperature furnaces that incorporate all these heat treatment techniques that are known for their heating uniformity, low maintenance needs, and cost-effectiveness.

Industrial Box Furnaces

Lindberg/MPH has long been a leader in the design and manufacture of thermal processing box furnaces. These heat treat furnaces save you money when treating large volumes of material per hour with exceptional uniformity and low maintenance.

Industrial Box Furnace Specifications

- Temperature Range: up to 2500°F

- Inert or Combustible Atmosphere Capable

Pit Furnaces

Lindberg/MPH offers a wide variety of pit furnaces in fuel fired or electric powered configurations that are easy to operate and control.

Key Specifications

- Temperature Range: up to 2000°F

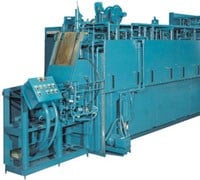

Conveyor Furnaces

Key Specifications

- Maximum Temperature Range: 400°C to 1100°C

- Inert or Combustible Atmosphere Capable

- Brazing, Soldering, Glass Sealing Process Capable

Vacuum Furnaces

Key Specifications

- Temperature Range: up to 2400°F

- Top Loading (Pit)

- Front Loading

- Integral Quench

Walking Beam Furnace

The Lindberg Walking Beam Furnace is a popular choice for sintering metallic and ceramic materials under controlled atmosphere. These energy efficient and cost effective Lindberg walking beam furnaces are capable of processing heavy loads at high production rates. Temperature range: up to 3272°F (1800°C) in reducing atmospheres.

Key Features

- Protected yet accessible hydraulic system

- Reliable and adaptable load transfer

- Flexible sequence control system featuring microprocessor based programmable control

- Proven refractory system

- Solid, round rod molybenum heating elements

- Multi-atmosphere capabilities & Rugged construction

Rental and Refurbished Equipment

- High Quality OEM Parts and Components

- Skilled Craftsman

- Rigorous Quality Control

- Hands on Support

- 1-Year Warranty